Oil Pump Control System

An automatic oil pump control system that monitors oil pressure and maintains proper levels in a crankcase

Project Overview

This project was developed to solve a real-world problem: maintaining proper oil levels in a crankcase. The system automatically activates an oil reservoir pump when the oil pressure light indicates low levels, while also providing a manual override option for maintenance or testing purposes.

At the heart of the system is an STM32 microcontroller that monitors the oil pressure sensor, controls the pump operation, and provides user feedback through status indicators. The design prioritizes reliability and safety for this critical mechanical system.

Schematic Design

The first step in creating the Oil Pump Control System was designing the electronic circuit. This schematic incorporates the STM32 microcontroller, input sensing circuitry for the oil pressure light, and driver circuits for controlling the pump motor. The design also includes status indicators and a manual control interface.

Schematic design showing the complete circuit for the oil pump control system

The circuit design includes several key features:

- STM32 microcontroller for intelligent control logic

- Isolated input for safely monitoring the oil pressure light

- MOSFET-based motor driver for the pump

- Manual override button with debounce protection

- Protection circuitry for handling automotive voltage spikes

PCB Design

With the schematic completed, I developed the PCB layout. The design needed to be compact, ruggedized for an automotive environment, and include proper thermal management for the switching components that control the pump motor. Special attention was paid to ground plane design and noise immunity.

PCB layout showing component placement and routing for optimal performance

The PCB design process addressed several important considerations:

- Separation of digital control and power switching sections

- Robust ground planes for noise immunity in the automotive environment

- Thermal management for the MOSFET and power components

- Connector placement for easy installation and servicing

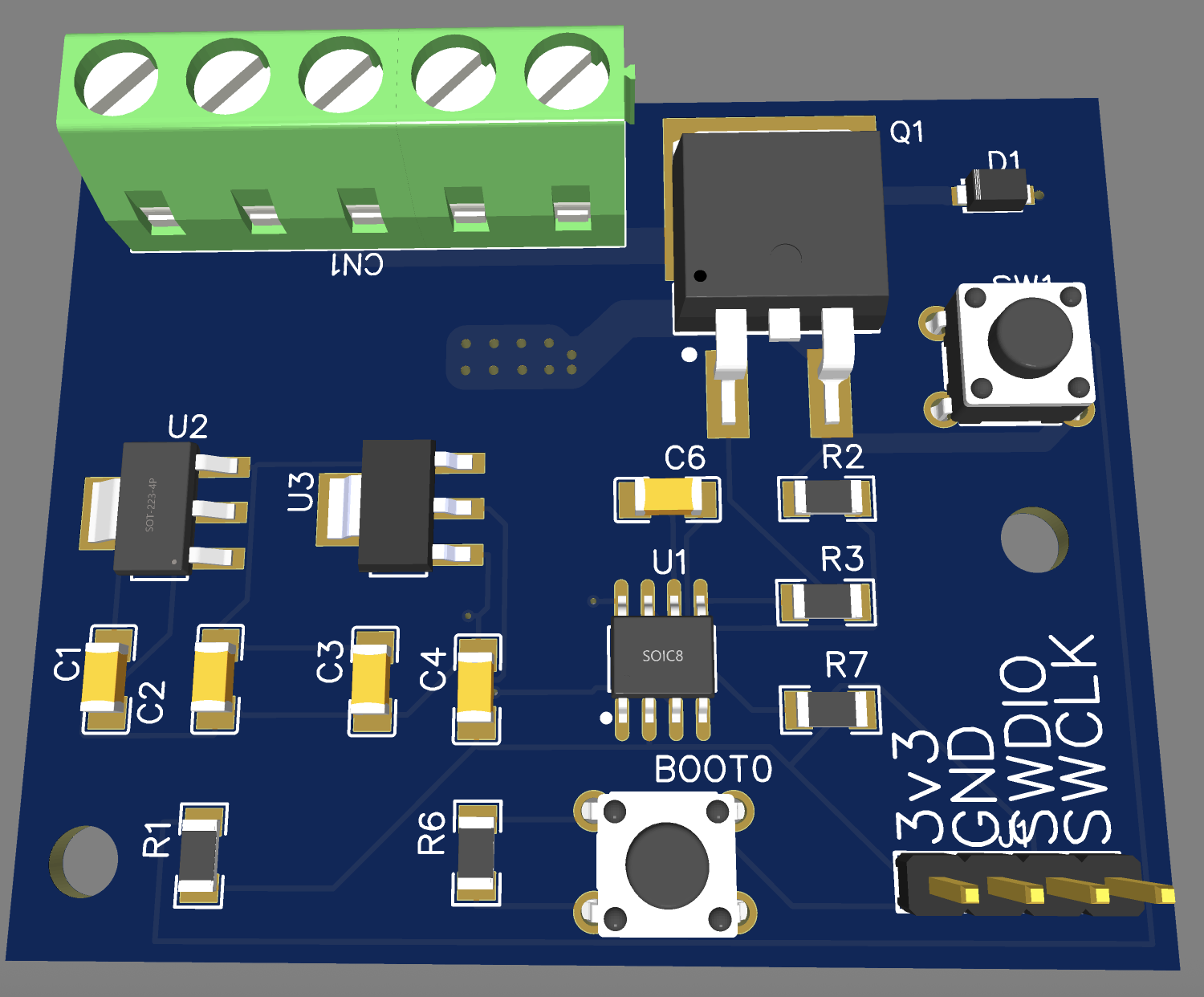

3D PCB Visualization

The final design step was generating a 3D model of the PCB to verify component clearances, connector accessibility, and mounting options. This visualization helped ensure that the board would fit properly in its intended location and that all components would have adequate clearance.

3D visualization of the PCB showing component placement and board dimensions

The 3D modeling process helped identify and resolve several design considerations:

- Clearance verification for tall components

- Connector orientation and accessibility

- Heat sink placement and thermal considerations

- Mounting point alignment with the enclosure

- Overall size verification for the installation space

Implementation & Firmware

After completing the hardware design, I developed the firmware for the STM32 microcontroller. The software implements the control logic that monitors the oil pressure light, manages the pump operation, and handles the manual override functionality.

The control logic includes several key features:

- Oil pressure monitoring with debounce protection to prevent false triggers

- Timed pump operation to prevent overfilling

- Manual override with safety timeout

- Watchdog timer for system reliability

The completed system provides reliable, automated oil level maintenance that reduces the risk of engine damage from low oil levels while requiring minimal user intervention.

Results & Benefits

The Oil Pump Control System has been successfully implemented and provides several key benefits:

- Automatic maintenance of proper oil levels in the crankcase

- Reduced risk of engine damage from low oil conditions

- Simplified maintenance with manual control option

- Clear system status indication

- Robust operation in automotive environments

- Protection against electrical interference and voltage spikes

This project demonstrates how custom electronics can provide elegant solutions to mechanical problems, improving reliability and reducing maintenance requirements.